MIL-F-18327F

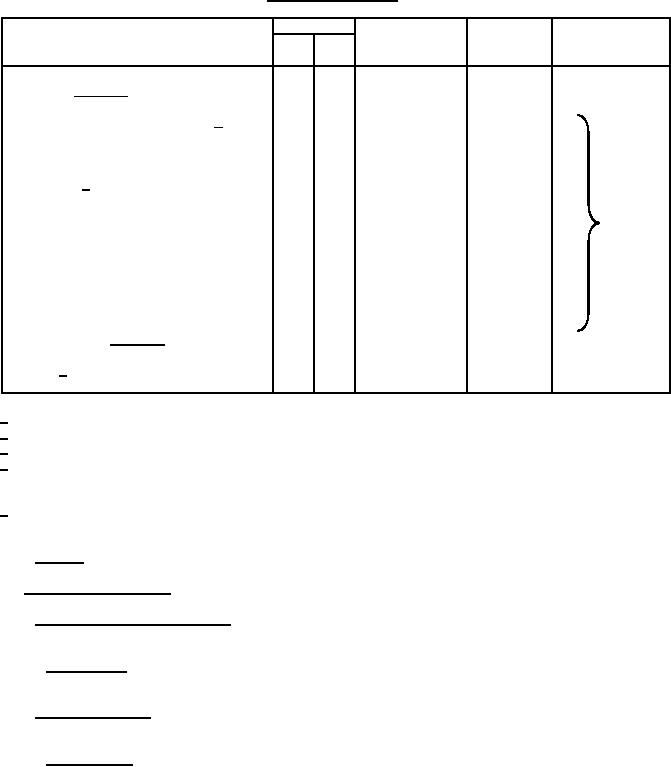

TABLE VI. First article inspection - Continued.

Inspection

Requirement

Test

Number of

Grades

paragraph

paragraph

sample units

4, 6 5, 7

to be inspected

8

9

Group III - Continued

Salt atmosphere(when specified ) 4/

X

X

Acceleration (when specified)- - - - - - - -

X

X

Electrical characteristics - - - - - - - - - - -

X

X

Visual and mechanical inspection

(external) 1/- - - - - - - - - - - - - - - - - - -

X

X

6

Resistance to solvents - - - - - - - - - - - - -

X

X

Flammability (external flame) (grades

5, 7, and 9 only) - - - - - - - - - - - - - - - -

---

X

3

Visual and mechanical inspection

(internal) - - - - - - - - - - - - - - - - - - - - -

X

X

3

Group IV

and 3.26

Fungus 5/ - - - - - - - - - - - - - - - - - - - - - -

X

X

2

1/ Nondestructive tests.

2/ For grades 4, 6, and 8 the torque test is applicable only to terminals with screw threads.

3/ Two sample units only.

4/ When salt atmosphere is specified, the six sample units shall be divided into two equal groups. Each group

shall be inspected, independently for moisture resistance and salt atmosphere. When these examinations are

performed in the foregoing manner, separate test data shall be submitted for each group.

5/ Test shall not be performed if the manufacturer provides certification that all external materials are fungus

resistant.

4.5.3 Failures. One or more failures shall be cause for refusal to grant first article approval.

4.6 Conformance inspection.

4.6.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B

4.6.1.1 Inspection lot. An inspection lot shall consist of all filters covered by a single procurement document or

drawing, produced under essentially the same conditions and offered for inspection at one time.

4.6.2 Group A inspection. Group A inspection shall consist of the inspections specified in table VII, in the order

shown.

4.6.2.1 Sampling plan. A sample of parts shall be randomly selected in accordance with table VIII. If one or more

defects are found, the lot shall be 100 percent screened for those quality characteristics found defective in the sample

and defects removed. After screening and removal of defects, a new sample of parts shall be randomly selected in

accordance with table VIII. If one or more defects are found in the second sample, the lot shall be rejected and shall

not be supplied to this specification.

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business